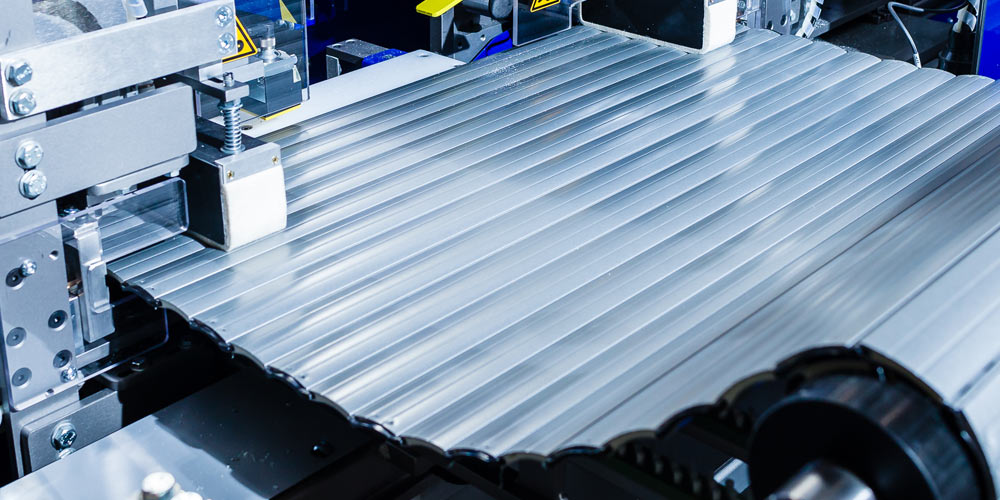

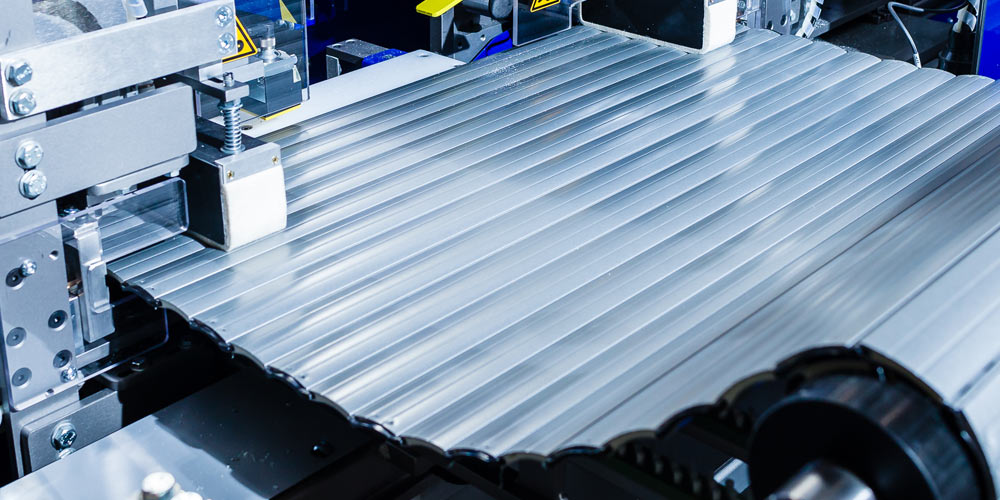

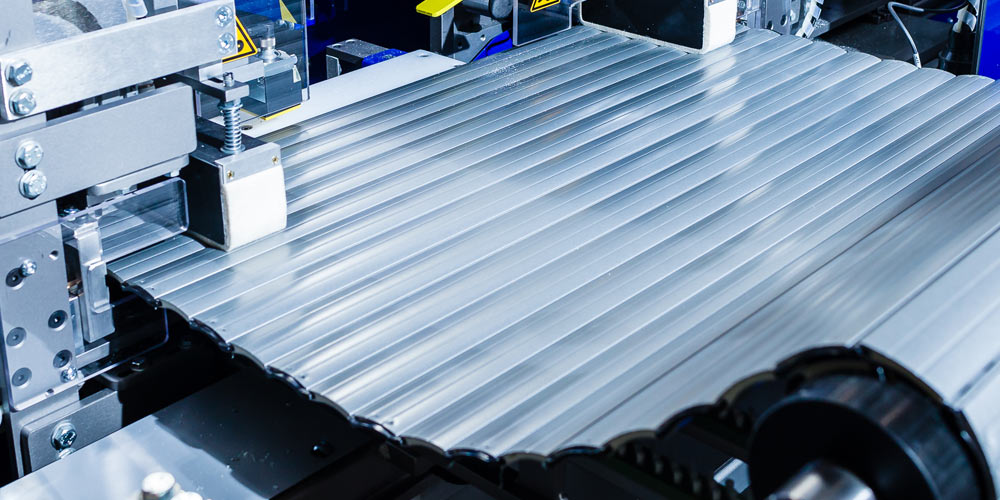

Our machines for roller shutter production

Aluminium or plastic (PVC), the choice is yours!

- Our entry-level model -

Automatic roller shutter armour locking machine with infeed for ALU slats already cut to size and end piece locking on both sides.

Production process:

The operator sets the width of the roller shutter in the machine by hand. For this purpose, a cut slat serves as a masterpiece. The machine has a swing-in stop on both sides (fixed and mobile part). The operator inserts one cut-to-size slat at a time into the machine, it is recognised and drawn in.

End pieces are automatically inserted into every second slat and embossed. A counter monitors the number of slats.

After the entered number of slats has been reached, the machine stops.

The machine can process different ALU slats in terms of geometry and width and is pre-set for one slat size.

Converting the machine to a different slat size is quick and easy.

- Our allrounder for ALU slats -

Fully automatic roller shutter armour locking machine with integrated saw for cutting to size and locking ALU slats with end piece locking on both sides.

Production process:

The perforated and non-perforated slats are fed onto the loading device. This means more efficient and faster work with the loading device and increases the capacity of the line. Of course, they can also be loaded individually, shoulder to shoulder.

The machine now automatically takes over slat by slat and pushes them against the width stop, after which they are cut to size.

Cut to width, the ALU slats are locked in place by automatically inserting the end pieces from each side of the slats and at every second slat. The end pieces are embossed on both sides. The roller shutter is automatically wound up.

We recommend processing the slats as carpets of 4 or 5 slats.

Remaining pieces smaller than 400 mm are automatically disposed of at the front in a collection container, larger remaining pieces are automatically disposed of at the back for recycling.

- Our racing machine -

Fully automatic roller shutter armour locking machine with quantity storage, double slat retraction, integrated saw for cutting to size and locking ALU slats with end piece locking on both sides.

Production process:

At the same time, 2 slats of 6 m each are drawn in, cut to size, transported further and locked in place.

Thanks to the quantity storage, up to 400 m of slats can be stored.

The slats are automatically wound up or laid flat.

The slats must be processed on the machine in a 4-piece or 6-piece carpet.

Remaining pieces smaller than 400 mm are automatically discharged to the front into a collecting container, larger remaining pieces are automatically discharged to the rear for further processing.

- our allrounder for plastic slats (PVC) -

Fully automatic roller shutter armour locking machine with integrated saw for cutting and locking PVC slats by wire locking.

Production process:

The perforated and non-perforated slats are fed onto the loading device. This means more efficient and faster work with the loading device and increases the capacity of the line. Of course, they can also be loaded individually, shoulder to shoulder.

Cut to width, the PVC slats are locked in place by automatically inserting an inox wire at every second slat. The roller shutter is automatically wound up.

The loading device can take up max. 6200 mm long slats. Therefore, we recommend processing the slats as carpets of 4 or 5 slats.

Remaining pieces smaller than 300 mm are automatically disposed of to the front in a collecting container, larger remaining pieces are automatically disposed of to the rear for recycling.

Our answer to the perfect locking machine for aluminium slats.

This machine convinces by its efficiency and simple operation.

The slats are quickly threaded and locked in place thanks to its automatic feed and sawing device.

Our answer to the perfect locking machine for plastic (PVC) slats. This machine convinces by its efficiency and simple operation.

Thanks to its automatic feed and sawing device, the slats are quickly threaded and locked in place by means of Inox wire.

We value quality, reliability and sustainability - with these maxims we want to satisfy you as our customer. With our excellent service, we offer you everything from a single source:

Let our experts advise you and increase your know-how in roller shutter production!

We look forward to your enquiry - give us a call, we'll be happy to help!