Precise drilling and cutting systems for guide rails - Efficient solutions for roller shutter production

Our drilling and cutting systems for guide rails offer a powerful and automated solution for processing aluminum and plastic profiles. With high repeat accuracy, short cycle times and flexible setting options, they enable economical production at the highest quality level. Whether drilling, milling or sawing - our systems are specially tailored to the requirements of the roller shutter and sun protection industry and can be seamlessly integrated into existing production processes.

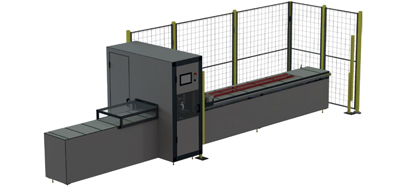

Drilling and cutting machine MP2C 3000

Drilling system with positioning gripper for processing roller shutter guide rails

Processing in pairs or individually.

Guide rails min. 500 mm

Guide rails max 3.000 mm

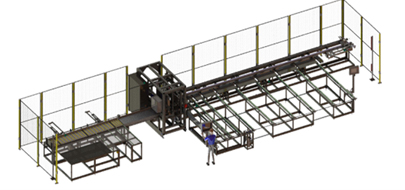

Drilling and cutting machine MP2C 6000

Drilling and cutting system with positioning pliers for processing roller shutter guide rails

Processing in pairs or individually.

Guide rails min. 450 mm

Guide rails max. 3.500 mm

More information

Guide rails in roller shutter production - precision, stability and functionality

Guide rails are a key component in roller shutter production and play a decisive role in the function, safety and durability of the entire system. They ensure that the roller shutter slats are reliably guided, prevent lateral slippage and enable the roller shutter to move smoothly and evenly.

Function and importance of guide rails

In roller shutter production, guide rails serve as a lateral boundary and guide for the roller shutter curtain. They are usually made of aluminum or plastic and are available in various profile shapes and surfaces - depending on the area of application and design requirements.

Production and processing

Modern drilling and cutting systems enable the precise processing of guide rails directly on the production line. Openings for fastenings, catches or accessories are precisely positioned and cut to size - for perfect integration into the roller shutter system.

Who are our systems made for?

Our machines are aimed at manufacturers of roller shutter and sun protection systems who rely on automated processes, consistent quality and short set-up times. Whether series production or individual special solutions - our systems can be tailored precisely to your requirements.

Why us?

With many years of experience in special machine construction and a deep understanding of the requirements of the roller shutter industry, we offer not just machines, but holistic solutions. From planning and production to commissioning, we support you with technical expertise and personal service.