State-of-the-art cutting systems for roller shutter production - quality that pays off

Automated cutting systems are indispensable in modern roller shutter production. They enable precise, fast and economical processing - a decisive factor for quality and competitiveness. Ready to take the next step? Contact us for a personal consultation or request a non-binding quote. Together we will find the right solution for your roller shutter production requirements.

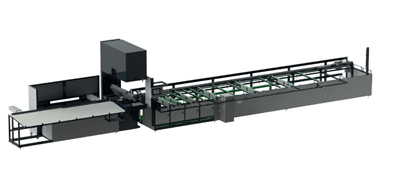

Cutting system for roller shutter axles RC AX 6000

Automatic cutting system especially for roller shutter axles

Roller shutter axles: max. length 6000 mm

Diameter: 40-100 mm

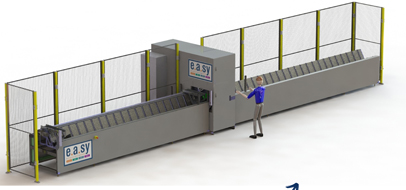

Cutting system for roller shutter profiles and roller shutter panels RC 6000

Fully automatic sawing system especially for cutting aluminium and PVC profiles and roller shutter panels to length

Up to 7 m long

Cutting capacity 300 x 300 mm

More information

What is a cutting machine for roller shutter axles?

A drilling and cutting machine is a specialized machine that automatically cuts roller shutter axles (also known as roller shutter shafts) to the desired length and at the same time precisely drills holes for fastening elements, motor mounts or accessories. These systems are designed for different shaft diameters and can be flexibly adapted to different production requirements.

Why our cutting systems for roller shutter axles?

Our cutting systems for roller shutter axles stand for maximum precision, efficiency and reliability - developed to meet the requirements of modern manufacturing companies. Here are three good reasons why you should rely on our technology:

1. maximum precision with every cut

Thanks to state-of-the-art control technology and high-quality components, our systems guarantee millimeter-precise cutting and drilling - regardless of the number of pieces or profile type.

2. automation for greater efficiency

Our cutting systems are designed for maximum productivity. Automated processes reduce manual work steps, lower error rates and increase output.

5. long-term investment security

Robust construction, low-maintenance technology and reliable customer service ensure that your system will continue to operate economically for years to come.